Need a Nitrogen generator in your plant!

With rising fuel and energy costs, the cost of liquid nitrogen is going up and is making it much easier to justify the purchase of a nitrogen generator in a wide range of purities and pressures. In a high percentage of cases, generating your own nitrogen using commercially available equipment is a very cost effective alternative to purchasing liquid nitrogen or cylinder nitrogen from traditional supply sources like the industrial gas companies. In some cases, the return on investment (ROI) ranges from six months to 2 years, but ROI can range, depending on several factors, to several years while still being a good investment.

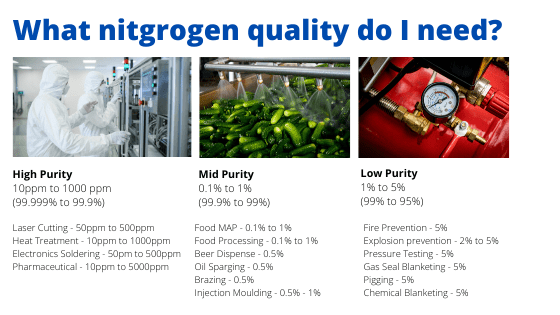

If you are considering purchasing a nitrogen generator for your facility the first question to settle is what nitrogen purity you actually need for your application and facility. Nitrogen purity is generally expressed as a percent, such as 99% Nitrogen (which means 1% Oxygen with the balance of nitrogen and other inert gases). In some high purity cases, it may be expressed as PPMv Oxygen remaining in the product gas. 10 PPMV is the same as 99.999% nitrogen. 10,000 PPMv equals 1% O2. The answer to the purity question can make or break a project’s budget and have a huge impact on the amount of electricity used. There are many factors to be considered. First, there are some basic dynamics common to nitrogen gas generation that should be considered.

The Technology

For the purpose of this article, we will focus on Pressure Swing Adsorption (PSA) Nitrogen Generator technology for the generation of Nitrogen Gas. PSA uses compressed air as the feed stock in the production of nitrogen. Pressure Swing Adsorption (PSA) uses, in most cases, two vessels, packed with a carbon molecular sieve (CMS). The CMS adsorbs Oxygen as compressed air flows upward through one of the vessels while the other vessel is depressurized and a small amount of the nitrogen output is flowing downward (counter flow) to drive off or desorbs the oxygen and moisture collected by the vessel when it was online removing oxygen from the air. The vessels alternate this adsorption and desorption process. There are several steps in the process; equalization, pressurization/depressurization, adsorption/purge, then back to equalization.

PSA technology is generally used where higher purities are needed, and in many cases if the system is very large in capacity. Over the last 15-20 years, there have been many advances in pressure swing adsorption (PSA) technologies. Improvements in carbon molecular sieve (CMS) used in PSA equipment has shown significant increases in flow rates and air to nitrogen ratios (ANR) have come down dramatically. The compressed air purification system treating the compressed air feeding the n2 Generator should consist of a Receiver(s), water separator, air dryer (selected carefully for the application), and multi-stage particulate and coalescing filters, all designed to meet the unique needs of a PSA system.

Nitrogen Purity Specification

The higher the nitrogen purity required, the larger the system to obtain a given flow rate. More compressed air will be required and more electricity consumed. Capital cost, long term maintenance cost, and floor space will increase as well. Whereas a 95% N2 system will take approximately 1.95 M3 of compressed air for 1 M3 of nitrogen, the ratio of air to nitrogen could be as high as 7.5:1 at 99.999% N2 in some systems. Here are a few “Rule of Thumb” Nitrogen specs for some industries (For Comparison Only)

Is the Nitrogen Purity the right one for my application?

The bottom line here is that most industrial nitrogen generation systems are “over spec’d” because the information is sometimes hard to obtain and so to be safe, consumers will often specify a higher purity of nitrogen than they need. Sometimes this comes from an equipment manufacturer, who has not done sufficient testing on various nitrogen purities. In the earlier days of nitrogen generators, this information was difficult to come by, but over the years more and more application specific information has become available. This can sometimes be obtained through industry associations and equipment suppliers, and industry professionals.

Energy Cost Implications Based on Varying Nitrogen Purities

In Table 1 below, ANR is the air-to-nitrogen ratio. This is the measure of the efficiency of the technology. Multiply this number by the N2 requirement (m3/min) to get the Volume (m3/min) of Compressed Air required. CCF is the Compressor Correction Factor. Size the compressor 1.15 to 1.2 times the required compressed air m3/min to allow for the compressor manufacturer’s flow tolerance and varying ambient conditions.

| Effects of Purity Selection on Energy Required | |||||||

| Generator Inlet 8.0 Bar | |||||||

| System Type | N2 Purity | M3/min N2 | ANR | M3/Min Air Req’d | CCF | Min Comp M3/Min | Compressor KW Req |

| PSA | 95% | 1.5 | 1.94 | 2.91 | 1.15 | 3.34 | 18kw |

| PSA | 99.5% | 1.5 | 2.42 | 3.63 | 1.15 | 4.17 | 30kw |

| PSA | 99.99% | 1.5 | 4.24 | 6.36 | 1.15 | 7.31 | 45kw |

| PSA | 99.999% | 1.5 | 7.45 | 11.17 | 1.15 | 12.85 | 75kw |

One can see how drastically the effects of the purity were chosen for the 1.5 m3/min nitrogen example. The compressor kw ranges from 18.5 to 75kw depending on the purity percentage of the nitrogen.

Table 2 below calculates the Overall Air Compressor energy cost for the compressor to produce the required Nitrogen Flow and Purity.

| Air Compressor Energy Cost P.a. @ various Purity Levels | |||||||

| Generator Inlet 8.0 Bar | |||||||

| Compressor Type | N2 Purity | Min Comp M3/Min | Air Compressor Specific Pwr | Total kw for Req’d Volume | Hours production P.A. | Kw/hrs p.a. Req’d | Energy Cost based on 0.10 cent per kw/hr |

| Rotary Screw VSD | 95% | 3.34 | 6.5 kw/m3/min | 21.71 | 8000 | 173,680 | €17,368.00 |

| Rotary Screw VSD | 99.5% | 4.17 | 6.5 kw/m3/min | 27.10 | 8000 | 216,800 | €21,680.00 |

| Rotary Screw VSD | 99.99% | 7.31 | 6.5 kw/m3/min | 47.51 | 8000 | 380,080 | €38,008.00 |

| Rotary Screw VSD | 99.999% | 12.85 | 6.5 kw/m3/min | 83.52 | 8000 | 668,200 | €66,820.00 |

Table 3 below calculates the Energy cost per M3 of Nitrogen produced.

| Energy Cost Per m3/N2 @ various Purity Levels | ||||

| Generator Inlet 8.0 Bar | ||||

| N2 Purity | M3/min N2 | M3/P.A. | Energy Cost based on 0.10 cent per kw/hr | Energy Cost Per M3/N2 |

| 95% | 1.5 | 720,000 | €17,368.00 | €0.024 |

| 99.5% | 1.5 | 720,000 | €21,680.00 | €0.030 |

| 99.99% | 1.5 | 720,000 | €38,008.00 | €0.052 |

| 99.999% | 1.5 | 720,000 | €66,820.00 | €0.092 |

Note: The above calculation does not include the Energy requirement of the system Air Dryer which dries the compressed air. If a refrigerant air dryer is used, then the additional cost is small adding only €0.00096 per m3/N2.

On-Site Nitrogen Gas Generation

On-Site nitrogen gas generation is an easy and reliable way that can save you money and give you more control over your gas use. Companies that produce their own supply of on-site nitrogen can generate as much or as little nitrogen as they need, at a fraction of the cost of having the gas delivered by an external source.

Benefits of On-Site Gas Generation

- Increased profitability – significantly lower unit gas cost, more up-time. Reduction in Nitrogen costs of up to 95%

- Increased reliability – gas available on demand 24/7, only pay for gas produced

- Sustainability – short payback on investment, long service life, low energy use, and reduced CO2 footprint

ENDS

N2 Generation Packages – O’Neill Industrial delivers bespoke, market-leading, high flow & high purity nitrogen generators as solutions for numerous applications within industry sectors, such as Food & Beverage, Pharmaceutical & Biotechnology, Chemicals, Electronics, Metals, Plastics, Rubbers and many more.

Leasing Options – O’Neill industrial can offer Nitrogen generation packages under five-year lease agreements. The advantages of leasing the equipment in contrast to buying can be multiple; you avoid large capital expenditure up front, get complete peace of mind and could potentially install a higher spec Nitrogen System which may have been cost prohibitive if you chose to buy outright.

Contact us today, email Austin[@]oni.ie