With the new E Series Oil Free VSD Air Compressor, Ingersoll Rand has established a clear advantage in the race for energy efficient oil-free air compressors with the lowest cost of ownership. The E Series is the only Oil-Free Air-Cooled Compressor on the market today with Heat Recovery as an option. In this post, we examine the impact of its performance at a large industrial site in the mid-west.

In 2022, O’Neill Industrial installed and commissioned a Model E160n Air Cooled Compressor complete with the Energy Recovery option for a client of Sensori Facilities Management. The compressor was selected with energy recovery and energy efficiency a priority. Reliability and after sales technical support were also important.

Energy Efficiency – Key Findings

- E Series provides more compressed air at less specific power consumption compared to competiton over the whole range

- ROI opportunity competition 160VSD v E160ne A @ average 85% capacity 8760 hours a year @ € 0.25kW/hr –

- 7.3 kW/(m³/min) – 6.8 kW/(m³/min) = 0.5 kW/(m³/min) 20.27m³/min x 8760 x 0.25 x 0.5 = € 22,195 saving per annum

Energy Recovery

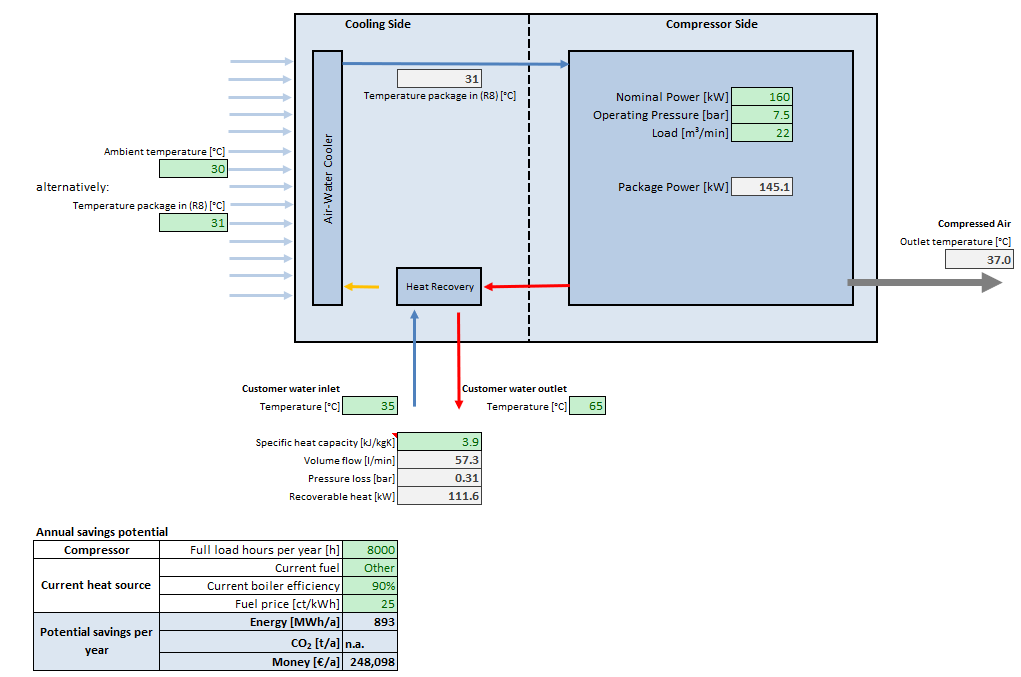

The hot water from the air compressor in Element 6 is used to heat water in a calorifier. The water from the calorifier is in turn used to heat feed water to a heat pump. The E 160n can recover 98% of the input electrical energy. If the unit is operated at full load, then up to €240,000 annual savings can be made (based on 0.25 cent kw/hr).

Reliability

With over 500 hundred units installed worldwide since the launch of the E Series Compressor, the reliability of the E series machines has proven to be exceptional. This is due to the robust design, high quality components and advanced features of the compressor.

After Sales Service

The E Series comes with the Ingersoll Rand Helix system as standard. Helix is IR IoT (Internet of Things), Remote Analytics Service and consists of a complete infrastructure:-

• Hardware – Modem connected to the Compressor controller

• Communication – 3/4G Mobile data transmission

• Software – Cloud Platform accessible on PC, Tablet, Smartphone

• Technical Support team

Helix™ monitoring gives you the power of real-time operating data for your compressed air systems, allowing you to:

• Optimise production planning and protect your investment

• Receive alerts and notifications of possible issues before production is interrupted

• Stay in touch with your compressed air system – anytime, anywhere

• Service schedules aligned to your operating hours

• The right information at the right time to inform your critical decisions

See more about Helix here

For more info or a quote, please contact Austin@ oni.ie