Heat Recovery

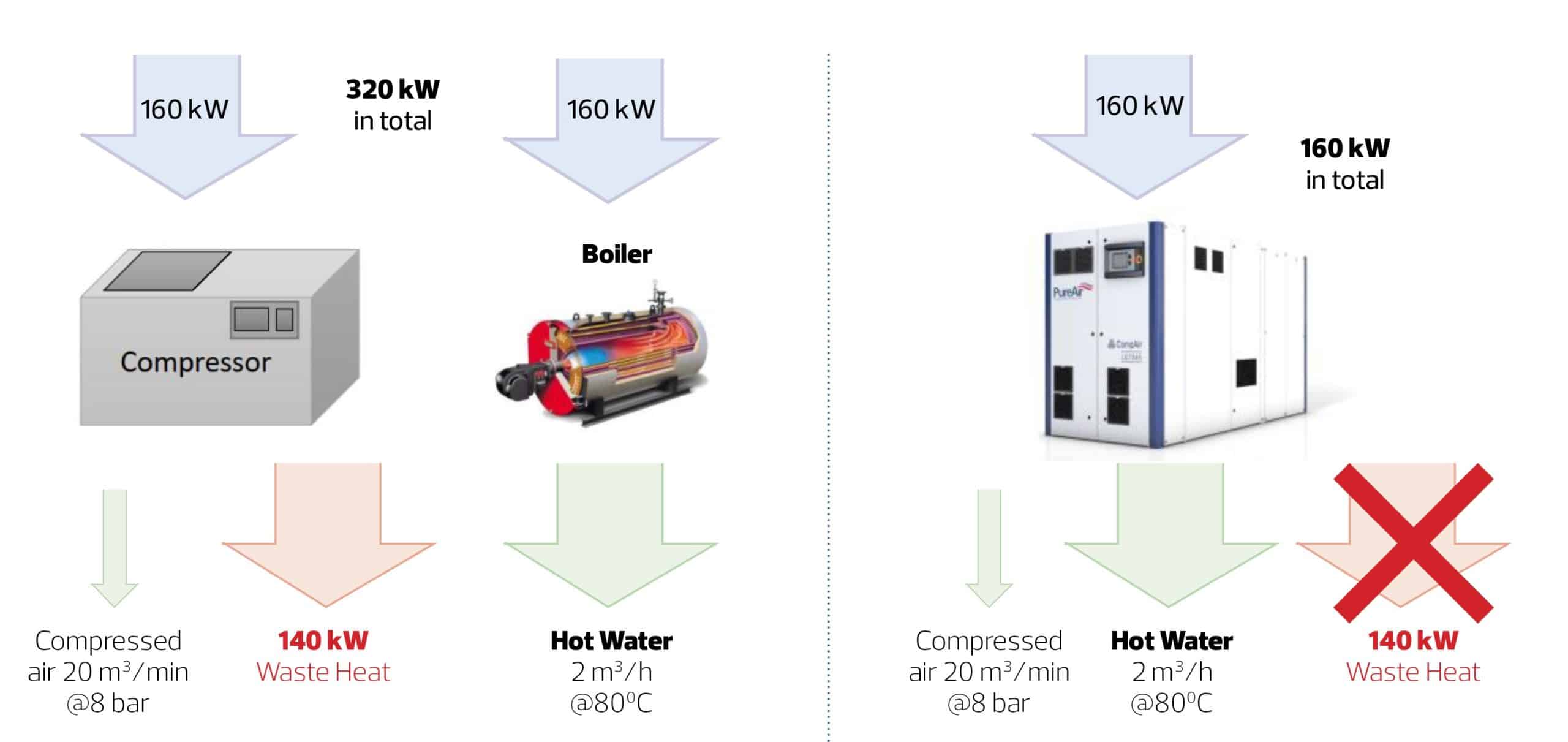

One of the largest areas of energy consumption within a plant is its compressed air system. Air Compressor energy costs can account for 10 percent or more of a company’s total electricity costs and make up approximately 80 percent of a compressor’s total cost of ownership. The overwhelming majority of the energy used to run a compressor is converted into heat through the compression process, and this heat is normally left to absorb into the cooling cycle. A heat recovery system will reduce your energy costs.

In this article we set out how heat recovery can reduce energy consumption and carbon footprint.

O’Neill Industrial / Ingersoll Rand offer three different options for Heat Recovery:

Option 1:

HEAT RECOVERY WITHIN AN AIR-COOLED OIL-FREE COMPRESSOR

Ingersoll Rand’s E Series Oil Free VSD Air Compressor with Heat Recovery as an option is the only Oil Free Air Cooled Compressor on the market today with Heat Reovery as an option. This eliminates the need for an external cooling water system i.e. cooling water pumps, Blast Coolers, pipe work, etc associated with water-cooled compressors. In the new Ingersoll Rand E Series Compressor, the heat exchangers, pump and controls are all within the compressor enclosure and you get usable water temperatures of up to 85°C.

Thousands of savings are achievable each year as not only does the Heat Recovery element reduce energy bills, the E-Series has the lowest specific power of any Oil Free, VSD, Rotary Screw Compressor (between 75kw & 160kw) in the market today – thereby, amplifying the ability to reduce operating costs. The potential energy savings can mean a return of investment in just two to three years.

Download the brochure

Option 2:

HEAT RECOVERY WITHIN A WATER-COOLED OIL-FREE COMPRESSOR

With water-cooled oil-free compressors, the Heat Recovery Solution requires the installation of a control unit between the compressor and the customers’ cooling and heating circuit. The compressor operates independently from the customers’ process.

Option 3:

HEAT RECOVERY WITHIN AN AIR-COOLED OIL-LUBRICATED COMPRESSOR

The Ingersoll Rand Energy Recovery System (ERS) provides a cost-effective way to reduce your energy bills and benefit the environment by capturing this heat and putting it to work. The Ingersoll Rand ERS coolant-to-water heat exchanger utilises the thermal energy captured in the compressor coolant to heat water up to 70°C (160°F).

Click here for further details

CASE STUDY

A Tipperary meat plant discovers unquestionable benefits of energy recovery

Contact us today sales[@]oni.ie or call 061-313888