SCHUNK is the world’s No. 1 for clamping technology and gripping systems, from the smallest parallel gripper to the largest chuck jaw programme.

Sales & Support - LIMERICK

+353 (0)61-313888

Sales & Support - CORK

+353 (0)21-4351137

Schunk’s unique modular centre sleeve system enables you best flexibility without taking the chuck off the machine spindle! ROTA NCO – For individual one-off applications. The 3-jaw high-strength chuck without chuck bore combines maximum jaw travel with the ultimate in clamping force. Already a big hit on vertical lathes. ROTA 2B – The two-jaw rock-solid chuck for high-power machining. Special features are maximum clamping force combined with large jaw travel and extremely rigid chuck base. Particularly popular in the manufacture of fittings and cast components. ROTA-S plus – The leading manual chuck with innovative quick-jaw-change system. The large through hole as well as best T.I.R. and repeatability, make it for the turning and also for the stationary application as a flexible all-rounder. Schunk is the market leader in chuck jaws for many years and offers the world’s largest standard line of jaws. Ground groove and serration SCHUNK is the first manufacturer worldwide to grind the groove and the fine serration of its soft standard chuck jaws instead of milling them. This results in improved repeat accuracy when changing jaws and ensures lasting precision in the base jaw serration. In this way, your top jaws, base jaws, and lathe chucks are preserved – allowing you to save money. Ground serrations also improve clamping stability and the quality of the workpiece surfaces, for optimum machining results Quentes fiberglass jaws Made of fiberglass-reinforced plastic, these jaws enable clamping on already ground or surface-treated surfaces, since they leave no clamping marks whatsoever on the clamping surface. In combination with the large looping angle of the turned Quentes on the workpiece, this ensures low-deformation clamping of the component. The high coefficient of friction of 0.3 – 0.4 makes it possible to transfer high torques with low clamping forces. The supporting jaws of the Quentes fiberglass jaws are made of aluminum. This provides a clamping solution that – due to its low weight – also enables high machining speeds. When they wear out, Quentes clamping inserts can be replaced easily, quickly and at low cost. The Quentes fiberglass jaws are available and in stock in two different standard models for power chucks and quick-change chucks. Serrated bars Quality, reliability, precision Schunk’s line of small components and universal gripper modules features high product quality, precision and diverse monitoring capabilities. The optimally graduated series covers the entire spectrum of workpiece sizes. Gripper modules from SCHUNK: High-speed with precision Robot accessories from SCHUNK: Swivel and rotary modules from SCHUNK – state-of-the-art technology for rotational movements Rotary modules from SCHUNK: SCHUNK – the world of linear technology Compact modular design for a combination of a wide variety of different modules to form one overall system. Depending on the load range and required stroke length, diverse components are also available for demanding tasks. Linear modules from SCHUNK: Modular products for reliable connections Robot accessories from SCHUNK include an extensive line of modules for the mechanical, sensor and power connections of handling modules and robots. Quick-change systems, rotary feed-throughs, anti-collision and overload devices, force sensors and compensation units and insertion units ensure optimum interplay between the robot arm and gripper. Robot accessories from SCHUNK: Systematic Assembly Automation – As easy as a modular system Flexible – Fast – Future-secure. This is the GEMOTEC system from SCHUNK. The comprehensive line of pneumatic and electric modules opens an unforeseen variety of combination possibilities. All actuators are compatible with each other. Where other companies still have to conduct design work, the GEMOTEC system is already assembled. Fast and straightforward. Sophisticated Precise Multi-functional Telephone: +353 (0)61-313888 Phone: +353 (0)21-4351137

SCHUNK is the world’s No. 1 for clamping technology and gripping systems, from the smallest parallel gripper to the largest chuck jaw programme.

Schunk Clamping Technology

Schunk Lathe Chucks

Schunk Chuck Jaws

Serrated bars allow customers to manufacture their own soft top jaws – easily, quickly and at low cost. The bars are available in steel or aluminum, with 90° and 60° fine serration and in a standard length of 420 mm. These bars also have a ground groove and serration for a longer service life of the base jaw and for high repeat accuracy when changing jaws.

Schunk Grippers

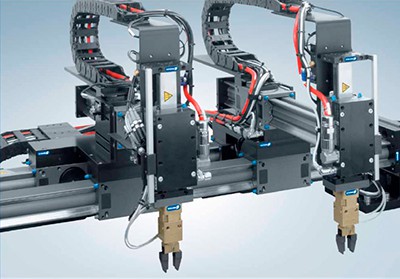

Pick and Place Unit

When performing pick & place operations, the SCHUNK modular system offers system integrators, machine builders and users a high degree of design freedom, cost effectiveness, flexibility and reliability with minimum planning, design and commissioning work. With the PPU-E Pick & Place Unit for automated assembly, SCHUNK has expanded this high-precision modular system.

Rotary Modules

The rotary module product line from SCHUNK offers a complete spectrum of compact swivel and rotary units for every handling task – and for fast and easy integration. Internal media feed-through guarantees reliable performance and minimises interference contours. Various sensor monitoring capabilities and multiple mounting options for all modules increases the flexibility during plant engineering.

Linear Modules

Robot Accessories

Modular Assembly Automation

Contact For Services

Limerick

Fax: +353 (0)61-314116Cork Office

Fax: +353 (0)21-4351143Email us for product information, pricing, service and availability