Hovione, a Portuguese pharmaceutical firm, acquired its Cork site in 2009. It was a stateof the art facility although, inevitably, they inherited some older equipment. In 2015, it was apparent the compressed air system needed to be replaced due to inefficiencies and reliability concerns. However, the company had a preference for leasing as opposed to buying the equipment in this instance.

Hovione appointed compressed air solutions experts, O’Neill Industrial, to provide a new state of the art compressed air system under a lease agreement. O’Neill Industrial provides lease agreements as a unique value added service to their customers.

Benefits of Leasing

The benefits of leasing the equipment in contrast to buying were multiple for Hovione; they have a fixed cost contract for 5 years with an option to purchase at the end and it covers all maintenance and emergency call-outs thereby giving them a solution that delivered reliability and peace of mind.

From an accounting point of view, there are no surprises. Hovione can control and operate the installation without significant drain on working capital, the fixed-rate funding makes budgeting easy as they have clear sight of future expenditures.

Austin O’Neill, an oil-free air compressor specialist with O’Neill Industrial, said: “The advantages of a lease purchase agreement means organisations avoid large capital expenditure up front and in some cases can install a higher spec more energy efficient Compressed Air System which may have been cost prohibitive if they chose to buy outright.”

Recommended Equipments

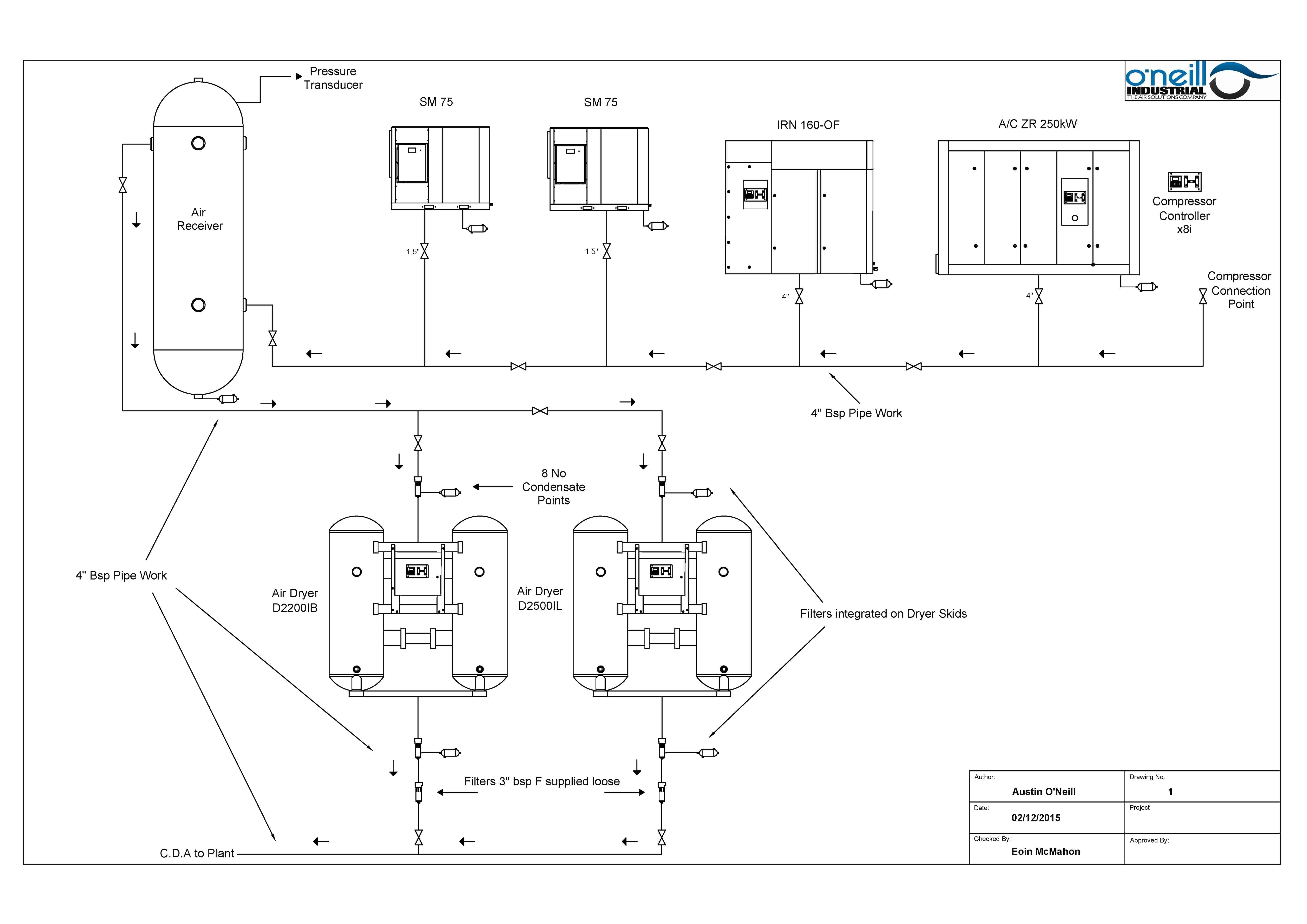

Having identified the needs of the plant, Kenneth Lloyd, Utilities and Site Services Manager at Hovione, designed the compressed air solution in collaboration with O’Neill Industrial. The high end spec included: two Ingersoll Rand Fixed Speed Compressors, an Ingersoll Rand Variable Speed Compressor, a Heat Regenerative Zero Purge Desiccant Air Dryer, a Heatless Desiccant Air Dryer, Filter Sets, Ingersoll Rand Intelligent System Controller Model X8I and an Ingersoll Rand Visualization Software Package for Air System Monitoring.

As part of the large scale installation, Hovione had to modify the controls and distribution manifolds to accommodate the project.

The new state-of-the-art compressed air system has been very successful. It has delivered improved reliability and energy efficiency. In addition, it has given Hovione far more control over operating costs and efficiencies due to the addition of the Ingersoll Rand VX Visualization Software Package for Air System Monitoring module which was added to the Ingersoll Rand Intelligent System Controller Model X8I

Ingersoll Rands X-Series System Automation products eliminate the complexity of compressor control coordination and increase energy efficiency. By adding the visualisation software they were given even greater control as they could access diagnostics on pressure and flow, service intervals and more. With a standard PC and Internet explorer, they can access System Visualization and monitor critical system and equipment parameters, drill down to individual compressors to view operational status and be alerted to any alarm messages.

Commenting on the success of the installation, Kenneth Lloyd, Utilities and site Services Manager, Hovione, said, “The key considerations for this project were cost and reliability. For Hovione, the leasing option afforded the most effective solution because it combined a fixed cost spread over a number of years and covers all maintenance and call outs in one tidy package. I now have an improved level of confidence in the reliability and efficiency of our compressed air system in meeting all of Hovione’s demands.”

About Hovione (www.hovione.com)

In it for life

Hovione is a Pharmaceutical Company dedicated to helping Pharmaceutical Customers bring new and off-patent drugs to market. We do well what is difficult, to give our customers what they cannot find elsewhere.

The Cork site has extensive facilities for drug substance manufacturing with approximately 430 cubic meters of state of the art cGMP capacity and the potential for 12 discrete process trains. The site houses the largest commercial pharmaceutical spray dryer available on the market, a Niro PSD-5, that is particularly suited for large volume products.