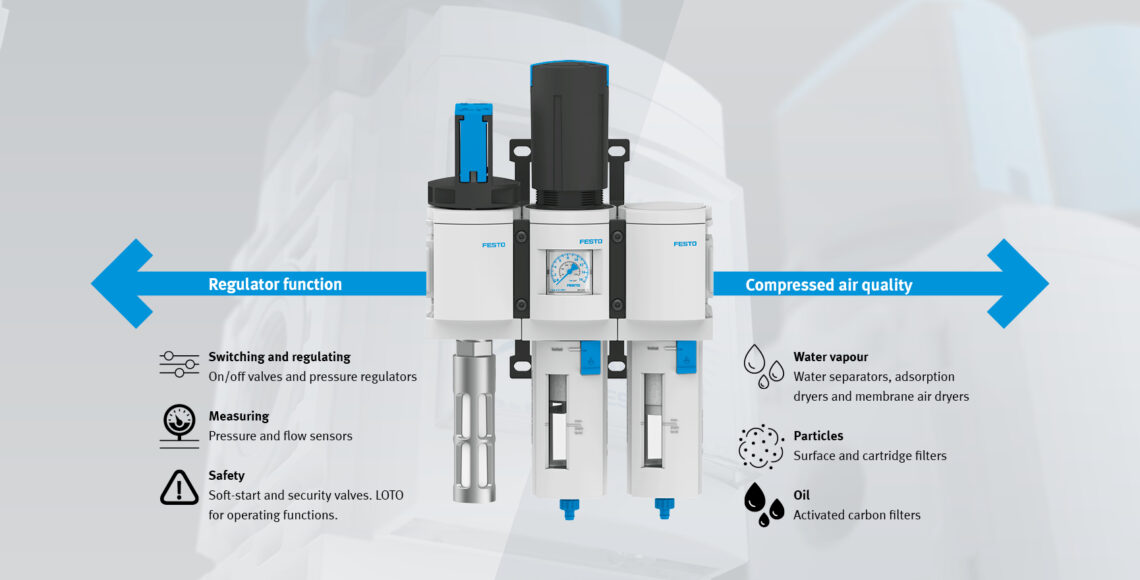

Air preparation is the basis for the right compressed air quality at the start of every machine or application. This is what determines the safety and reliability of all pneumatic systems.

Check out this useful diagram for the basic guidelines and variables

Compressed Air Preparation in Pneumatics

Air preparation that is tailored to your needs will significantly improve the service life of components and your system availability. Particles, water and oils contained in the compressed air can lead to mechanical friction, corrosion and clogging reducing the service life and functionality of components and systems. They also impair productivity and energy efficiency. Proper preparation, on the other hand, significantly increases process and product reliability, and it increases the availability of your system.

This white paper contains information on:

• How air preparation improves the process reliability, machine availability and service life of all components

• The criteria for choosing the best service unit and which physical principles need to be taken into account

• The functional principles and areas of application of the different service units

• How to configure a service unit for optimum performance

Download the White Paper – Compressed air preparation in pneumatics