Industry’s bid to achieving best-in-class energy efficiencies from compressed air has suddenly become more affordable with the launch of Ingersoll Rand’s game-changing E Series Oil Free VSD Air Compressor.

E-Series Oil Free Compressor

In this article, Austin O’Neill of compressed air specialists O’Neill Industrial looks at how Ingersoll Rand’s E-Series, the first and only air-cooled oil-free compressor on the market with optional heat recovery, provides a cost-effective way to reduce energy bills and benefit the environment by capturing the heat of compression and putting it to work.

Austin’s Remarks About the Efficiency of Compressor

“One of the largest areas of energy consumption within a plant is its compressed air system. Compressor energy costs can account for 10 percent or more of a company’s total electricity costs and make up approximately 80% of a compressor’s total cost of ownership. The overwhelming majority of the energy used to run a compressor is converted into heat through the compression process and this heat is normally exhausted to atmosphere or creates extra cost through the cooling of water in the case of a water-cooled compressor” said Austin O’Neill.

“We all know improving the performance of your compressed-air system reduces your plant wide energy costs. And while companies striving to reduce their Co2 footprint might have considered heat recovery as a nice-to-have in the past, there is now a real affordable option,” he continued.

The new E-Series oil-free rotary screw air compressor uses state-of-the-art design features to achieve unparalleled energy efficiency. Uncompromising in the superb reliability you expect from Ingersoll Rand, these compressors provide continuous 100% oil-free air as per ISO 8573-1:2010 Class 0 with the added feature of also being Silicone free. The E-series offers an optimized total package for risk-free operation at a low total operating cost.

While the E-Series has numerous impressive features, including on average 13% lower specific power consumption than competitor machines, a superior drive design, the smallest footprint (37% smaller than industry standard), lowest noise levels, and so much more, it is the optional Heat Recovery on the Air-cooled model that we’ll focus on today.

Why Heat Recovery?

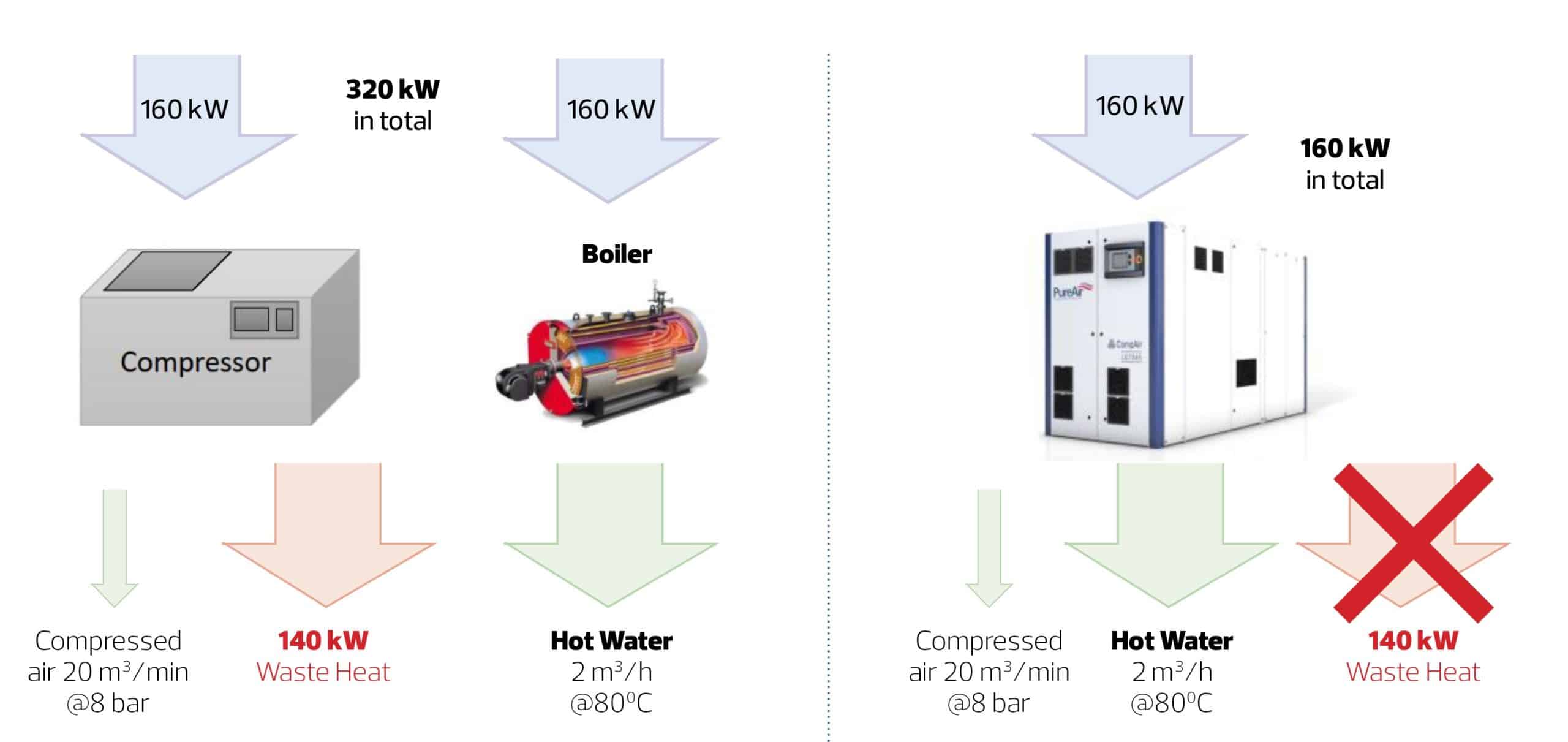

More than 90% of the energy input into a compressor is converted into heat. Without heat recovery, this heat is directly blown to atmosphere (cooling air, radiation heat) or creates additional costs (re-cooling of cooling water) in the case of a water-cooled compressor.

Until now, to heat water using rejected heat from an oil free compressor, the compressor had to be water-cooled with water from an external cooling water system. Now, for the first time, this is possible within an Air-Cooled Oil Free Compressor unit, eliminating the need for the external cooling water system i.e. cooling water pumps, Blast Coolers, pipe work, etc associated with water-cooled compressors.

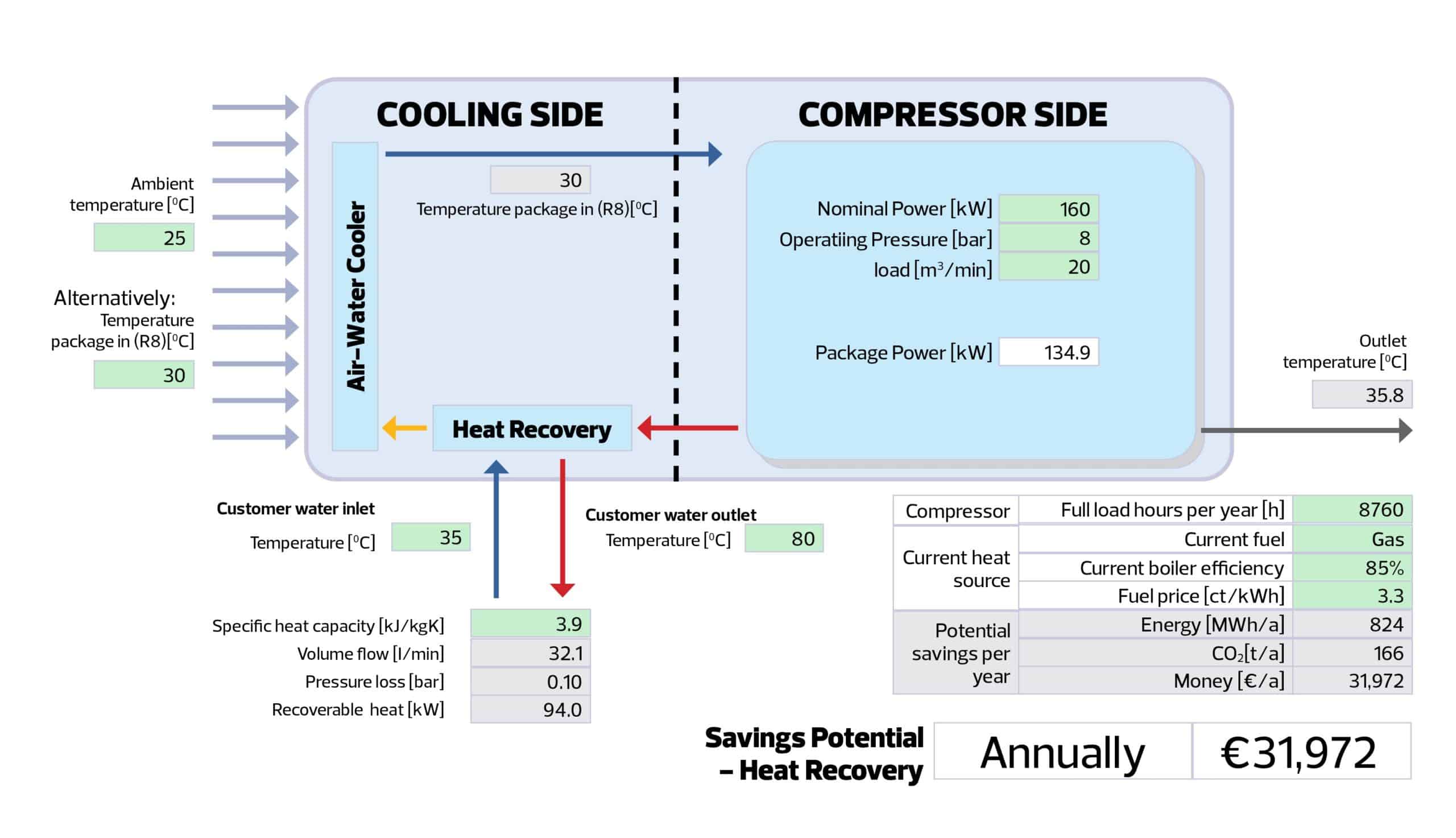

In the new Ingersoll Rand E Series Compressor, the heat exchangers, pump and controls are all within the compressor enclosure and you get usable water temperatures of up to 85°C.

Hot water recovered from the compressed air system can be used for sanitary purposes and space heating, but it is particularly suitable for process applications. Using the hot water as boiler pre-feed or directly in processes requiring up to 85°C you can lower the cost of energy sources such as natural gas or heating oil.

Saving Measures Give Fast ROI

Thousands of savings are achievable each year as not only does the Heat Recovery element reduce energy bills, the E-Series has the lowest specific power of any Oil Free, VSD, Rotary Screw Compressor (between 75kw & 160kw) in the market today – thereby, amplifying the ability to reduce operating costs. The potential energy savings can mean a return of investment in just two to three years.

Footnote: Under the same C.A. load conditions, if we adjust the inlet and outlet temperatures of the customer water to (Inlet temperature at 15°C and Water Outlet 30°C) the recoverable heat is 152.5 kw resulting in a Yearly saving of €51,860.00!

Leasing Makes it More Affordable

It is possible that a new E-Series Compressor will not cost the user anything! Companies wanting to avoid a large capital expenditure outlay can lease the E-Series from O’Neill Industrial and install the system straight away. O’Neill Industrial provides lease agreements as a unique value-added service to their customers. The monthly lease repayments in many cases can work out less than the savings achieved through reduced energy bills. This means potential profitability from the day the E-Series is commissioned.

For companies wanting to reduce their operating costs and achieve their sustainability goals, Heat Recovery is now a real and viable option.

For more details on the calculated savings, visit https://oneillcompressedair.com/products/heat-recovery/