Economical, precise, safe and energy efficient: drive and control technology from Bosch Rexroth moves machines and systems of any size.

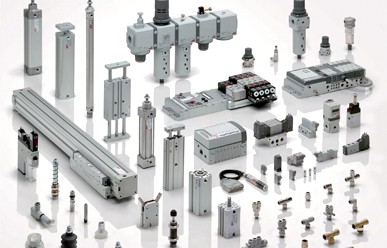

Bosch Rexroth provides an extensive product range which includes; assembly technology, electric drives and controls, gear technology, industrial hydraulics, linear motion technology, mobile hydraulics, moulding and casting technologies, pneumatics, welding technology, and tightening technology. Bosch Rexroth is the perfect partner for mechanical and plant engineering and supplies automation components as well as innovative solutions.

Assembly Technology: Material and Information Flow Technology

Years of experience, durable products and innovative technology are the main characteristics of the Rexroth transfer systems. The programme includes double belt and accumulation roller conveyor systems to transport weights of just a few grams up to 300 kg. Identification systems are integrated to control the workpieces in the system and to document quality assurance data.

With just six different, highly-integrated basic modules, the flexible assembly and transfer system MTS 2 for small and medium-sized series meets all the requirements of an efficient transfer system. You can convert this system in a matter of minutes without having to interrupt production.

In the factory automation sector, there is an ever-increasing demand for conveyor systems that can transport, store and position workpieces in a horizontal as well as vertical direction. VarioFlow, the new chain conveyor system from Rexroth, offers numerous convincing factors: it costs less than other chain conveyor systems and boasts better performance statistics.

Whether you are looking for a simple conveyor circuit or a more complex production system, Rexroth material and information flow technology is used for production, assembly and testing tasks throughout the world.

Manual Production Systems from Rexroth

Production demands can change rapidly. Whether it’s a change in production quantities, new product variants or product generations, the Manual Production Systems from Rexroth are flexible enough to adjust to any need. Rexroth’s Manual Production Systems were developed to give the very best in ergonomic solutions and lean manufacturing. The main concern of modern production is to avoid waste. The MPS Manual Production Systems from Rexroth have been developed strictly in line with aspects for lean production, enabling simple and fast planning and implementation of lean production installations. The demands on modern, lean production are more than just focusing on individual modules. In fact, an integrated system with a uniform implementation concept comes to the forefront. At Rexroth, this concept is reflected by the MPS philosophy.