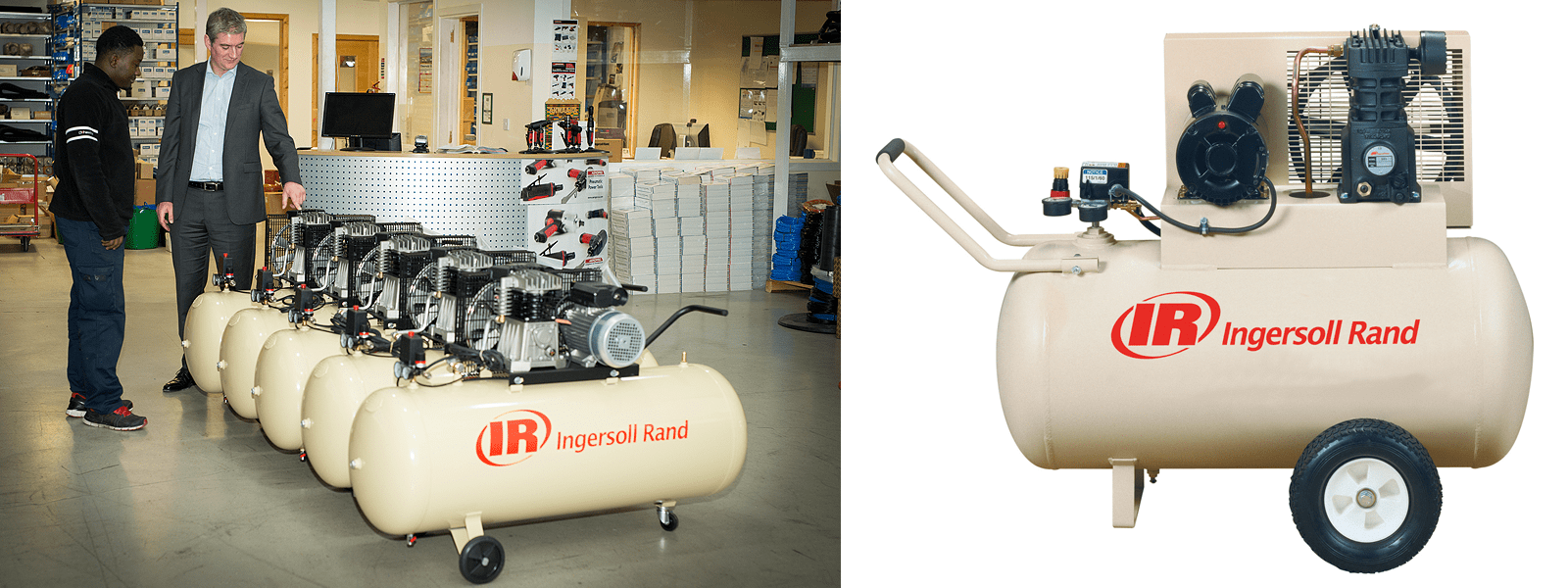

With a proven design and stellar track record, the Ingersoll Rand reciprocating air compressor family has earned worldwide recognition for reliable, trustworthy performance that saves money and enhances business success through:

- Lower life cycle costs

- An ability to thrive in punishing applications

- Configurations that meet varying needs

- Optimum solutions for greater efficiency

Aluminium

Stationary Fixed Receiver

Stationary Silenced Belt drive

Ingersoll Rand’s long-lasting, market-leading single-stage and two-stage reciprocating compressors and accessories are ideal for auto body shops, small garages and DIY projects, offering a range of small air compressor models including portable and lubricated systems.

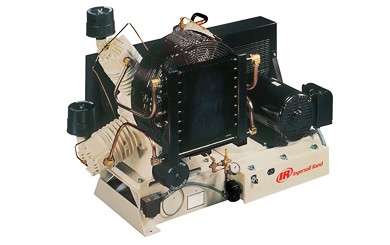

High Pressure

The Ingersoll Rand Type 30 high pressure units, used in industries such as refuelling stations, PBM, power plants and engine starting, are a series of base-mounted piston compressors that can provide your customer with pressure as high as 345 barg. Consistent with the 2-stage lubricated range, the high pressure units offer reliability, durability and ease of maintenance.

Download Small Reciprocating ESA Family brochure

Non-Lubricated

The Ingersoll Rand Type 30 non-lubricated piston compressors, used in industries such as textiles, packaging and chemical, do not have oil in the cylinders and are designed for applications where oil free air is required. The non-lubricated units use PTFE rings and rider bands to achieve cooling in the compression are. The Type 30 oil-free piston air compressor is available in both receiver mounted and base-mounted configuration.

Download brochure

2-Stage Lubricated

Ingersoll Rand offers two Type 30 reciprocating compressor packages to help meet the diverse needs of customers. The Value Package provides an economic and dependable solution for commercial, automotive and light industrial applications where the focus is simply on having a reliable compressed air system. The Premium Package enhances the durability and performance of the compressor by including an air-cooled aftercooler, low oil level switch and an auto-condensate drain (on receiver mounted units). These additional features make the Premium Package ideally suited for manufacturing and heavier duty industrial applications.

Download brochure

Contact For Services

Limerick

Telephone: +353 (0)61-313888

Fax: +353 (0)61-314116

Cork Office

Phone: +353 (0)21-4351137

Fax: +353 (0)21-4351143

What Is a Reciprocating Air Compressor?

Reciprocating air compressors, also known as piston air compressors, operate via positive displacement. In a typical piston compressor configuration, consisting of two stainless steel valve discs and a valve system, the piston moves downward and pulls air into a cylinder. The larger of the two discs flexes, allowing the air to pass through. The piston then moves upward, causing the larger disc to flex and form a seal against the valve seat. This process forces compressed air through a hole in the valve seat.